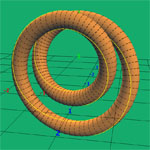

Segmented sculptures start out with computer simulation using a special software program that I wrote for this purpose.

This allows me to plan the amount of twist required in each segmented ring.

It also allows me to rotate the sculpture and view it from all angles to make sure that the over-all

balance of the piece is pleasing.

The wood is cut into strips at angles, and assembled into long staved tubes.

The tubes are turned on the lathe to a uniform diameter.

Then they are cut into individual segmented rings.

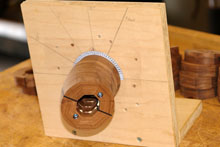

The rings are all sanded to a carefully controlled angle.

Note that it is important to orient each ring with the proper twist while sanding.

Numerous fixtures are made to hold each numbered piece in the proper orientation.

The tapered rings are assembled together with glue and screws.

The reason I screw the rings together is because it's easier than making fixtures for clamping.

It is most important to make sure each ring has the proper twist relative to it's neighbors.

Again, special fixtures are made to assure that the twist does not accumulate any error.

The segmented rings curve to form a closed doughnut, which is mounted on the lathe and turned again

to remove small discontinuities.

The doughnuts are then cut apart and reassembled.

Again, special fixtures are made to assure the pieces are assembled at the proper angles.

The joints are pinned with small wood dowels, then hand sanded for a smooth transition.

Most sculptures are finished with a hand-rubbed oil finish.